What is PFRO?

Conventional RO doses antiscalant to prevent scaling in a high recovery RO process, and chloramine or biocides to prevent biofouling. Stability in concentration, flow, and gauge and osmotic pressure are the best conditions for the formation of scaling, fouling and biofouling. Stability of the membrane surface geometry also contributes significantly to all forms of fouling.

IDE proprietary, patented Pulse Flow RO (PFRO) technology is completely contrary to Conventional RO operation. The flow is not stable, and the osmotic and gauge pressure change frequently and rapidly. The membrane geometry breathes according to changes in feed and permeate pressure.

This method has six times the ability of the standard RO process to remove concentrated solute ions or fouling particles. In between brine discharge pulses, the RO membrane operates in dead-end mode, with 100% recovery.

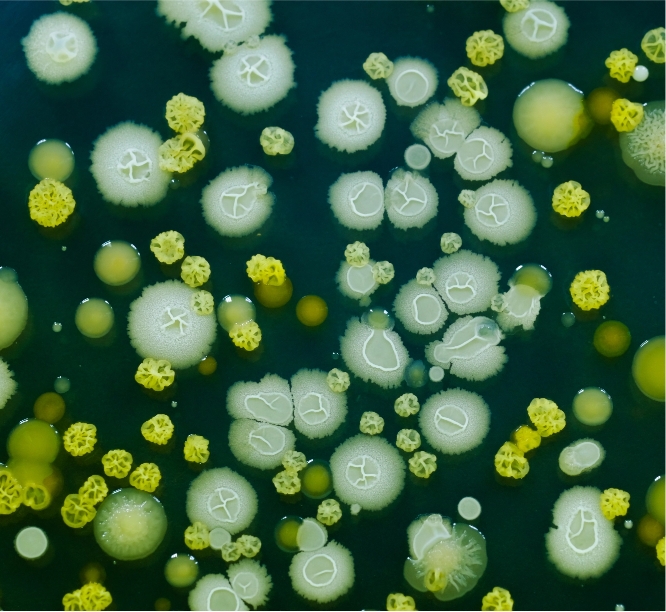

Bio Fouling in Conventional and PFRO

Bacteria become a problem for the RO process only when the biofilm is well developed. During the production cycle the gauge and osmotic pressure interchange in a non-exact parallel pattern. Bacteria are exposed to rapid changes in gauge and osmotic pressure.

The capacity of organisms to respond to fluctuations in gauge and osmotic environments is limited, and such fast changes do not enable them to reproduce.

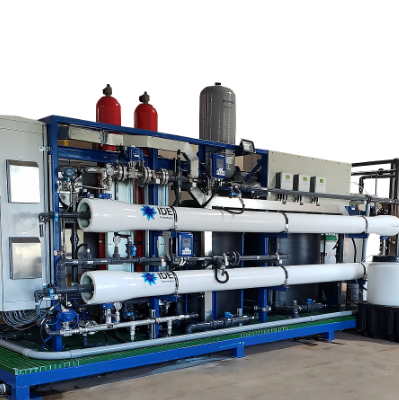

Structure of Conventional RO and PFRO Train

The PFRO train is single stage, with all the pressure vessels operating in parallel, contrary to the several-stage conventional BWRO and wastewater train.

Get the webinar:

Revolutionizing The Recovery of a Brackish Water RO Plant

Learn how IDE’s new Pulse Flow RO solution maximizes brine minimization and revolutionizes the plant recovery rate using a range of techniques

Download

Cutting Edge Technology for Brine Minimization and the Highest Recovery

The continuity of brine flow has been an unshakeable foundation of the conventional RO desalination process for almost 50 years. The leap from continuous to pulse flow process, allows achieving significantly higher solute concentration in the brine flow, as well as higher recovery. This prevents bio and other types of fouling.

Power consumption is reduced due to non-continuous brine pumping and diminished pressure drops in stages. Pulse Flow reduces the number of pressure vessels and membranes due to an equal pressure distribution between the membranes. A single-stage structure without inter-stage boosters reduces cost.

IDE’s PFRO solution for brine minimization can be designed into new plants or retrofitted into existing facilities.

Get the webinar:

Eco Reuse Pulse Flow RO (PFRO) for Water Reuse Applications

Learn from the experts on how to execute the smartest water reuse plan, enhance brine minimization, maximize recovery and minimize costs.

Related Solutions

All solutions

Related Projects

-

Central Coast Blue – Pismo Beach (USA)

Eco-reuse, Wastewater treatment, Municipal

Read more

-

Cherokee Wastewater Treatment Plant (USA)

PFRO, Wastewater Treatment, Municipal

Read more

-

Abilene Water Treatment Plant (USA)

PFRO, Wastewater treatment, Municipal

Read more

-

Wastewater Treatment for a Semiconductor Manufacturer (Israel)

Semiconductor, PFRO, Wastewater treatment, Water treatment

Read more

Let’s talk about your water needs