What is Reverse Osmosis Desalination?

Seawater Reverse Osmosis desalination is a mechanical process in which a pressure greater than the natural osmotic pressure is applied on seawater that passes through a semipermeable membrane (RO membrane) which rejects the salts in seawater, creating a stream of fresh water and a separate stream of concentrated seawater.

Reverse Osmosis Desalination Process

RO desalination removes all mineral ions and other dissolved solids, bacteria, and viruses in the water, making it a suitable process for desalinating water for both potable and industrial uses. Saline feedwater (seawater/brackish water /other saline streams) passing through pretreatment process to be compatible with the RO membranes by removing particles, suspended solids, and others before the RO separation.

The RO process removes all mineral ions and other dissolved solids, bacteria, and viruses remained in the feedwater, producing “product water” (fresh water). The product water from the membrane requires further adjustment (post treatment), making it suitable for drinking, industrial, agricultural, and other uses.

Taking the lead in RO desalination

For desalination to be a sustainable, affordable, and long-term solution to the water needs of the planet, it aims to be carbon neutral. IDE is constantly improving its desalination plants designs to minimise its carbon footprint. A safe and healthy work environment is a top priority for IDE, and to achieve this, we work in close partnership with our customers to deliver success and growth.

Flexibility – IDE provides small to large-scale, as well as modular desalination plants.

Capacity – We have built desalination plants capable of desalinating more than 3.5 million m³/day

Proven track record – Close to 60 years of desalination success have proven IDE’s ability to deliver complex projects on time, within budget, and meeting our clients’ standards while often exceeding their expectations.

IDE set a new benchmark for the price of desalinated water in some of the largest desalination plants procured under concessions of water project (BOT, IWP, BOOT) (e.g., Hadera, Soreq 1, Soreq 2)

Lowest Cost of Ownership

IDE’s reverse osmosis desalination plants deliver the industry’s lowest water costs over the lifetime of the plant, driven by:

Customized pretreatment systems – assure maximum RO desalination membrane longevity.

Proprietary pressure center design – combining highest efficiency high pressure pumps and other process design elements to increase operational flexibility, minimising downtime, lowering energy consumption and reducing costs.

Unique membrane configuration – increasing efficiency while minimising investment.

Saving Time & Money with a Prefabricated Modular Design Approach for Desalination Plants

IDE has developed an economical and sustainable solution for building desalination plants that dramatically reduces the installation time by up to 70% and offers significant CAPEX and OPEX savings. The unique, highly pre-engineered, and pre-assembled modular design minimizes costly on-site installation time.

Modular Design – The large modules of 12 skids can produce up to 32,000 m3/day of product water. Its modular design enables plug-and-play assembly of the system. The number of skids can be adjusted in accordance with the customer’s requirements. Moreover, any plant can be easily expanded to meet changing needs.

Cost-effective – Each skid is precisely sized to fit a 40-foot container. This enables quick and cost-effective transportation to the desalination plant while reducing the entire train’s installation time at the designated location.

Energy Efficient – A skid-mounted energy recovery system can also be added as part of the overall design. This makes the system highly energy efficient.

RO Desalination Procurement Models

IDE has a proven track record of delivering projects under several procurement contracting models, such as EPC, turn-key, BOT, concessions, DBOM, etc.

Cutting-edge Technology

IDE has a long track record of technological breakthroughs. These are some of the latest:

Pressure Centre Design – allows reduced energy consumption, increased system availability, and better reliability due to the efficiency of large high-pressure pumps and energy recovery devices.

Boron Removal System – a patented process that removes boron ions to concentrations below 0.3ppm, thus adjusting the water quality for agriculture.

IDE MPD modular design- a unique, highly pre-engineered, and pre-assembled modular design that minimizes very expensive on-site installation time. The fabrication and assembly are performed in a controlled environment at our workshops, including most high-pressure weldings and fittings, thus increasing the system’s quality and reliability.

Additional Solutions

All solutions

Related projects

-

Carlsbad Desalination Plant (USA)

Desalination, Reverse Osmosis, SWRO, EP, O&M

Read more

-

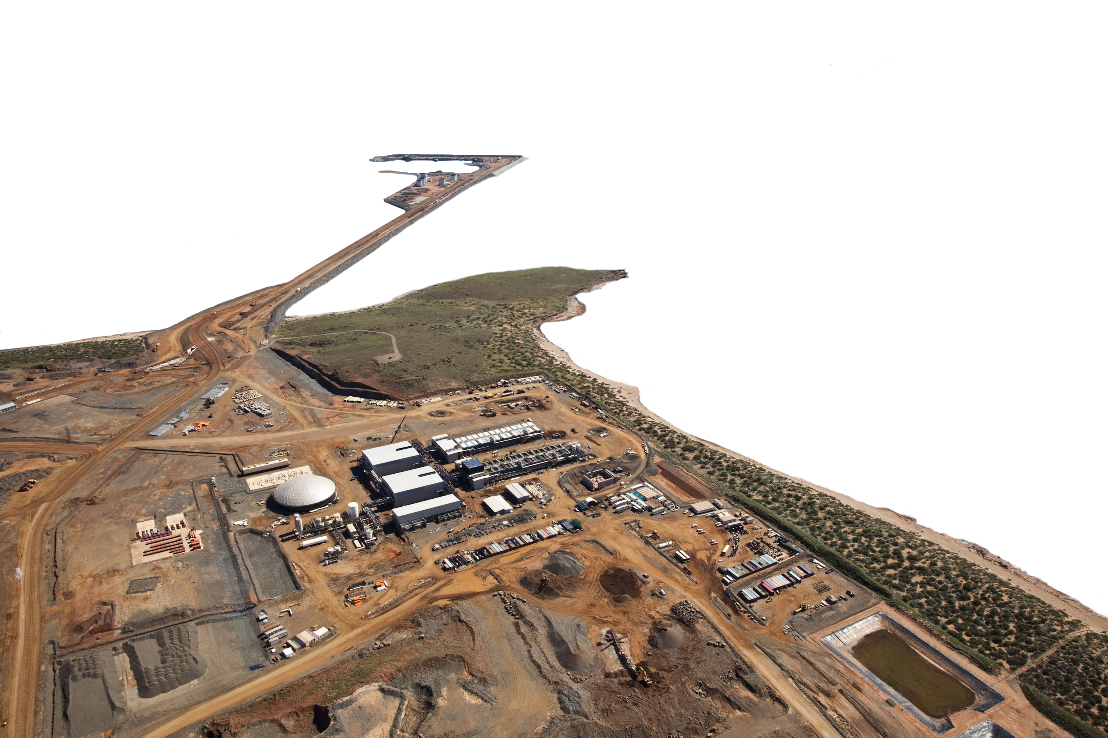

Sino Iron Ore Project (Australia)

Desalination, Reverse Osmosis, EPC&S

Read more

-

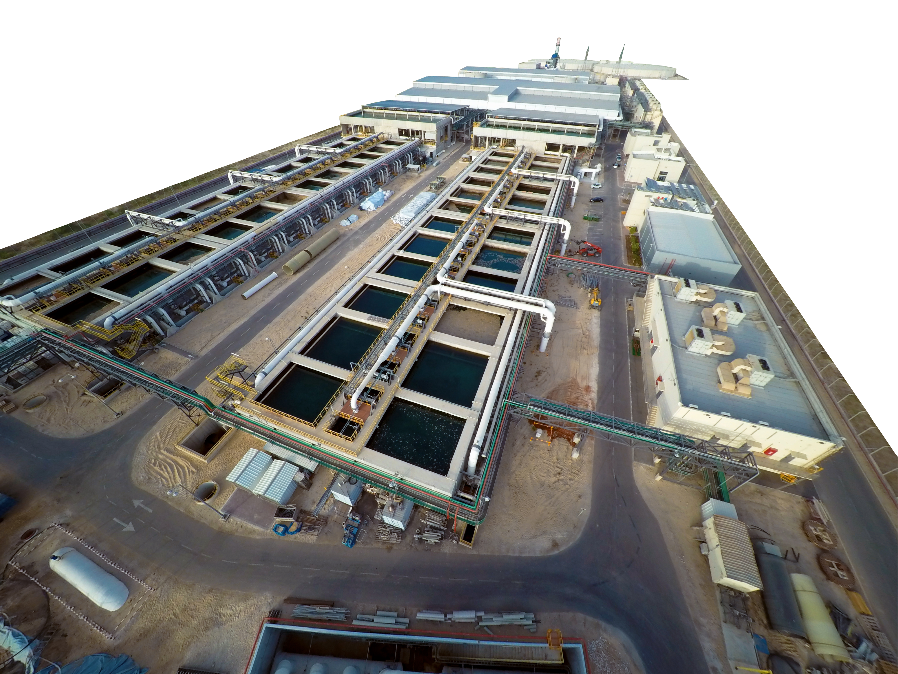

Sorek I Desalination Plant (Israel)

Desalination, Reverse Osmosis, BOT, EPC, O&M, P3, Municipal

Read more

-

Hadera Desalination Plant (Israel)

Desalination, Reverse Osmosis, BOT,EPC, O&M, P3, Financing, Municipal,

Read more