Pretreatment

Physical filtration water pretreatment is a crucial step in safeguarding downstream processes. It effectively removes harmful pollutants and particulates, thereby protecting and enhancing the efficiency of other systems, such as dissolved solids removal (including reverse osmosis, ion exchangers, and EDI) and biological treatment systems. This essential process ensures the smooth operation and longevity of the entire water treatment infrastructure. Some recommended core pretreatment industrial water physical filtration processes are:

Physical Separation: This process removes suspended solids like grit, sand, and organic matter through techniques like screening, filtration, and sedimentation.

pH Adjustment: Industrial processes can alter wastewater pH, making it too acidic or basic to allow for a safer process downstream.

Chemical Treatment: By adding specific chemicals, dissolved metals and others, inorganic compounds can be removed by precipitation.

Oil and Grease Removal: Many industries generate oily wastewater. Pretreatment employs techniques like skimming, flotation, or coalescence to separate and remove oil and grease before they can interfere with biological processes.

These core pretreatment processes work together to significantly reduce pollutants, making the wastewater suitable for the downstream process. Overall, pretreatment safeguards and optimizes the performance of the entire wastewater treatment plant.

By employing these core physical filtration processes, industries can ensure comprehensive water pretreatment, providing safe operational procedures, reduced maintenance costs, and prolonged equipment life for the entire wastewater treatment cycle.

At IDE we offer a complete range of pretreatment solutions

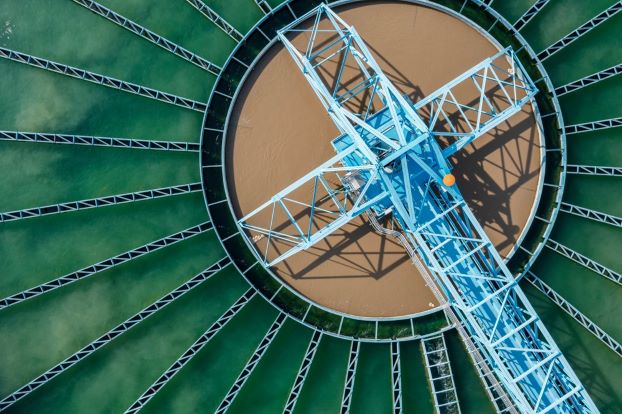

Clarifiers

Clarifiers, a primary part of any water treatment plant, operate on a principle of gravity settling to remove suspended particles, thereby reducing the turbidity and total suspended solids (TSS) of the raw water. Depending on the presence of inlet-suspended solids, a coagulation and flocculation process can also be envisaged at the inlet of the clarifier. Settled solids from the clarifier underflow are collected and transported to the sludge treatment area. This process is suitable for removing/treating high levels of Turbidity and TSS, as well as oil.

Lamella Clarifiers

Lamella clarifiers serve to remove heavy particles by settling into inclined plates. This separation method requires prior flocculation and coagulation steps. Lamella clarifiers are designed to maximize the settling efficiency of suspended particles with minimal footprint. This process is suitable for removing/treating Turbidity and TSS.

DAF (Dissolved Air Flotation)

DAF technology is an efficient procedure for the separation of suspended matter (turbidity, algae etc.) and oil from the wastewater. Dissolved air flotation (DAF) utilizes the property of micro-bubble adherence to suspended solids and oil, increasing the tendency of the particles to float. These micro-bubbles attach themselves to discrete floc particles created in the flocculation process.

Thanks to the velocity of air bubbles under flow and the decreasing density of aggregates, these aggregates rise to the water surface. DAF enables efficient separation of suspended solids, oil and grease traces, as well as reduction of organic load, and delivers significant cost savings (CAPEX), especially to small and medium plants.

UF (Ultrafiltration)

Ultrafiltration (UF) is a membrane filtration process that uses hydrostatic pressure to force water through a semipermeable membrane. The pore size of the ultrafiltration membrane, usually 0.01 to 0.1 micrometers (microns), creates a pressure-driven barrier to suspended solids, bacteria, viruses, endotoxins, and other pathogens to produce water with very high purity and low silt density.

Lime Soda Softening

Lime Soda Softening is a chemical precipitation method to remove the hardness in the raw water. In this method, chemicals such as lime (CaO/Ca(OH)2) and/or sodium carbonate (Na2CO3) are added to the raw water, based on the water chemistry, to remove the permanent as well as temporary hardness. This process is suitable for removing/treating Calcium and Alkalinity.

Filtration (Media filters)

A multi-media filter is used to reduce the level of suspended solids (turbidity) in process water. These suspended solids can consist of small particles such as silt, clay, grit, organic matter, larvae, zooplankton, algae and other microorganisms. The filtration degree of a multi-media filter depends heavily on the filter media and flow velocity through the filter. As particles become trapped in the media, the differential pressure across the bed increases.

GAC (Granular activated carbon)

Granular activated carbon (GAC) is a hybrid mixture of a wide variety of graphite particles. GAC removes contaminants through a process called adsorption, where contaminant molecules cling to the vast surface area of the GAC particles, getting pulled out of the water. Depending on the type of GAC and its activation process, it can target specific contaminants like organic compounds, taste & odor, causing agents, or even certain heavy metals.

Related Solutions

All solutions

Contact an Expert