About

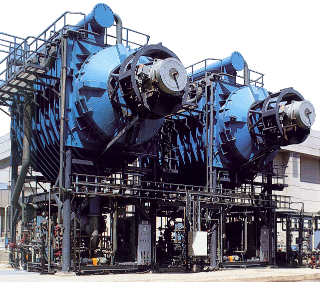

IDE provided a comprehensive solution to a large semiconductor manufacturer that needed to treat its fab’s industrial wastewater in order to maximize water reuse, minimize environmental impact, and meet local regulations.

In this project’s scope, IDE installed its proprietary Max H2O Pulse Flow RO (PFRO) system. This solution treats brine and effluents from two related applications: The Cooling Tower Blowdown (CTBD) and the PFRO unit. The product water from the PFRO system serves the fab’s needs, thus achieving the desired high recovery while reducing the external water withdrawal. The PFRO unit’s recovery rate stands at 54% and will ultimately increase to 88%.

- Capacity: 2000 m³/day

- Water Source: Brine RO and CTBD

- Technology : Pulse Flow RO (PFRO)

- Contract Type: Engineering, Procurement, supply, supervision of erection, startup & commissioning

- Location : Israel

- Customer : Industrial

- Usage : Industrial use/Reuse as cooing water.

- Commissioning : Jan 2022

Highlights

-

High recovery

Recovery of additional 54% from the upstream treatment system brine, resulting with an overall recovery rate of 88%.

-

Technological leadership

IDE’s proprietary patented single-stage PFRO technology overcomes the challenges of conventional RO operation by discharging brine in a pulse flow regime through short, high-velocity surges.

-

Low maintenance requirements

System configuration simplifies the preventive maintenance approach by utilizing IDE’s smart CIO (Clean In Operation) with short and frequent cleanings during the system operation , which increases the time between CIPs and the overall system availability