What is MAX H2O?

Increasing regulatory pressure and growing environmental awareness are driving the need for better brine minimization – one of the greatest challenges currently facing the water treatment sector.

The most economical approach to brine minimization would be to increase the load on the reverse osmosis stage and maximize its recovery as much as possible, thereby reducing the size of the thermal crystallization unit to the minimum. However, three major factors limit the recovery of any RO system:

osmotic pressure, the chemistry of the feed water, and low brine flow through the membranes associated with high recovery.

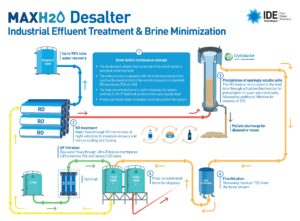

IDE has developed a process that overcomes these limitations and supports brine minimization: MAXH2O DESALTER.

The MAXH2O DESALTER is applicable for RO brine and industrial effluents with high scaling tendency and low to moderate salinity.

The MAXH2O DESALTER operates by recirculating treated water through the RO system at high shear velocity and continuously precipitating supersaturated salts from the recirculated brine. This significantly reduces the salt concentration build-up near the RO membrane wall and prevents the precipitation of sparingly soluble salts on the membranes. The salt precipitation unit downstream reduces the saturation of sparingly soluble salts in the recirculated brine. This allows continuous cycles through the RO system until reaching maximum brine osmotic pressure.

Seven good reasons to choose the MAXH2O DESALTER

- High recovery rates – limited only by osmotic pressure and not by supersaturation of sparingly soluble salts.

- Able to achieve different total recovery levels in the same system – the brine recirculation can be stopped at any recovery, at any RO brine level.

- High flexibility – operates with variable feed water qualities, concentrations, flows and recoveries.

- Membrane elements are exposed to variable salt concentration or variable osmotic pressure during the operation, reducing the biofouling potential.

- At the beginning of every cycle, the last elements are exposed to under-saturated water conditions, which reduce the tendency for scaling and improve the ability to dissolve scale.

- Semi-batch RO system with an integrated salt precipitation cycle for continuous desaturation of RO brine.

- Low investment and operational costs.

Related Solutions

All solutions

Let’s talk about your water needs