As AI adoption accelerates, data centers have become the physical backbone of the digital world, powering everything from virtual assistants to predictive analytics and.

Recover, Recycle, Reuse: Water Recovery & Reuse to Ensure Water Resiliency

Limited water resources combined with the growing demand for freshwater, changing weather patterns and wastewater discharge concerns have made water reuse a growing focus for industries and municipalities in recent years.

What is Water Recovery and Reuse?

Also known as water recycling or reclaimed water, water reuse is the process of capturing wastewater, stormwater, saltwater or graywater and treating it as needed for purposes such as domestic consumption, industrial processes, surface or ground water replenishment and watershed restoration. The term municipal wastewater reuse commonly relates to the process of tertiary treatment

followed by desalination, which produces potable water from wastewater at a fraction of the cost, compared to seawater desalination.

Across countries, communities and businesses investing in water reuse are ensuring that residents have safe drinking water supplies, industries have water to expand and create jobs, farmers have water to grow food, our environment is protected and our economic future remains secured.

Water reuse can improve water resilience, security and sustainability through a more diverse water portfolio. In recent years, more and more countries are incorporating water reuse into their water management strategies, as a proven method for ensuring a drought-proof, safe, reliable, locally controlled water supply.

According to a recent survey by Bluefield Research, the Reuse market stands at $1.8 billion and is expected to grow 27% by 2027. In the US alone, the volume of produced recycled water is projected to increase from 4.8 billion gallons/day to 6.6 billion gallons/day by 2027, marking a staggering increase of 37%.

<< Speak to a water reuse expert >>

ReUSe – The US Reuse Landscape

Overall, a growing trend in water reuse is evident in the US. According to Bluefield Research, 39 of 50 US states currently have reuse regulations or guidelines in place, with 3 more in the process of adopting regulations. Florida, the leading state for installed water reuse capacity, is considered a largely mature market, whereas California, the southern states and the Midwest represent the greatest opportunity for near-term growth, especially in industrial reuse opportunities.

A Florida golf course being irrigated with reclaimed water (Source: Shutterstock)

A Florida golf course being irrigated with reclaimed water (Source: Shutterstock)

Although California is as reuse-ready as Florida, it does have a close relationship with water recycling that started long ago. Beginning with the first use of recycled water for landscape irrigation 100 years ago, agencies across California have continued to innovate and improve the process to treat and beneficially reuse their wastewater. In 1962, California pioneered potable reuse with the Montebello Forebay Groundwater Recharge Project, which uses recycled water to replenish local groundwater supplies. Today, recycled water supplies offset approximately 9% of the state’s urban water demands, and agricultural reuse provides reliable water supplies for farmers throughout the state.

Increased use of recycled water provides a long-term, reliable water supply source and is an important water resource strategy for increasing drought resilience in regions throughout California. Water recycling is also a critically important strategy for environmental protection and efficient use of water for the state. By safely and effectively reusing water for potable and non-potable purposes, many areas of the State are able to reduce current and future reliance on environmentally-stressed imported water sources.

In 2015, approximately 360M m3/year of recycled water was used for agricultural irrigation in California, representing 31% of the total amount of recycled water used in the state.

<< Read more about our Pismo Beach demo case study >>

Paving the Path Towards Water Security – Reuse in Singapore & Neighboring Countries

Singapore’s successfully executed water supply initiative called “Four National Taps” has set an impressive precedent for its neighboring nations to follow. This robust, diversified and sustainable water supply system is based on four “water pillars”: high-grade reused water – also called NEWater, local catchment (i.e. rain and stormwater reservoirs), imported water (primarily from Malaysia) and lastly – desalinated water.

Singapore’s skyline (Source: Shutterstock)

Singapore’s skyline (Source: Shutterstock)

This integrated water management approach maximizes the efficiency of each source, addresses the water-intensive needs of the local industries, and serves the growing awareness towards environmental issues such as climate change, expanding urbanization, the rising cost of energy and the imminent global water crisis.

Neighboring countries have also implemented similar plan of action to establish water stability, drawing inspiration and principles from the Singaporean model. The premise was simple – four main water strategies that, when intertwined, are designed to solidify the nation’s resilience against frequent natural disasters and seasonal water scarcity.

These ambitious goals to dramatically augment the national water supply have led a few Far-Eastern countries to diversify their water resources between natural and artificial resources, such as reclaimed water.

As with all industries, some of the top Far-East industrial sectors, led by the semiconductor industry, are extremely water-intensive in their day-to-day operation. To add to the challenge, these industries are typically located in populated areas, and compete over the use of the same natural freshwater sources, leading to a growing need for smart, cost-effective industrial water treatment solutions.

The unique ability to produce substantial quantities of high-quality water while maintaining a minimal environmental impact and adhering to the strictest regulations, have led the Far-Eastern water reuse market to gain serious momentum in recent years.

<< Speak to a water reuse expert >>

IPR or DPR?

One of the most relevant aspects of the changing views regarding water reuse is the recognition of its importance in an integrated plan for the management of water resources. This approach has even been recognized by the United Nations through the 2017 World Water Development Report (Source: UNESCO) focusing on wastewater as a resource. Moreover, successful stories of water reuse have expanded the frontier from agricultural and landscape irrigation and restricted urban uses to a variety of uses including potable reuse.

What is IPR and DPR and what is the difference between them?

Two potable water reuse options are currently gaining prevalence: direct potable reuse (DPR) and indirect potable reuse (IPR). In the case of IPR, treated wastewater is released into groundwater or surface water sources, and later on reclaimed and treated to meet potable water standards. In the case of DPR, purified water created from treated wastewater, is introduced directly into a municipal water supply system without an environmental “buffer” of any kind.

After decades of IPR applications, a combination of improved effluent water quality, advanced treatment technologies and increasing demand for water supplies has finally sparked the interest in DPR. Focusing on the US, while states such as California, Arizona, New Mexico, Texas and Oklahoma are actively moving towards the adoption of DPR, other states prohibit DPR use and employ IPR methods exclusively.

Therefore, despite a noticeable trend and an overall readiness to employ more reuse applications, the US is still slightly behind countries such as Singapore when looking at widespread deployment of DPR. This is mainly due to stringent regulation and overall public concern, evolving the potential health hazards of DPR, if not performed with meticulous care.

While there is no reliable epidemiological evidence that the use of reclaimed water for any of its applications has caused a disease outbreak in the US, potential transmission of infectious disease by pathogenic organisms, or the release of organic contaminants, remain the principal public concerns regarding DPR (Source: Frontiers in Environmental Science). This hesitation is fairly ungrounded in developed countries, as proven by dozens of tightly-regulated DPR facilities across the globe, that produce high-quality potable water while adhering to the strictest health standards.

<< Read more about our Pismo Beach demo case study >>

Wastewater Reuse for Industrial Applications

The main industrial sectors that are utilizing wastewater reuse are power plants, food & beverage industries, chemical manufacturing, hydraulic fracking, oil & gas and petrochemicals. Industrial cooling towers have long been seen as an ideal repository for wastewater, because of the large volumes of water necessary for the evaporative cooling process.

What are the main factors driving the need for better and more advanced industrial water reuse technologies? In most cases, these are water scarcity and the ability to reduce costs by maximizing water recovery, as well as increased awareness of Corporate Social Responsibility (CSR). Some industries, however, are still hesitant to adopt reuse solutions on a wider scale.

Industrial users typically think of water management issues at their facility from two perspectives: securing water supplies for operations (including supply and discharge) and complying with quality standards for wastewater discharge. On the one hand, putting in place a smart reuse management plan helps facilities reduce their freshwater demand and their generated wastewater volume, minimize subsequent discharge permits, bring down the costs of freshwater acquisition and effluent treatment, and in some cases even provide recycling opportunities for certain industrial by-products.

On the flip side, properly managed reuse requires knowledge, financial investment and, understandably also modification of current operations for both DPR and IPR applications. Weighing the pros against the cons, implementing a reuse management plan often proves to be the most sustainable, resource-efficient, cost-effective and environmentally-oriented alternative.

Evolving regulation supports more rapid reuse market growth, and encouragement at the legislative level is also a key factor contributing to market readiness. Therefore, despite minimal pushback, all predictions indicate a much broader adoption of water reuse management plans in industrial facilities across the globe.

Spotlight on Reuse in the Power Sector

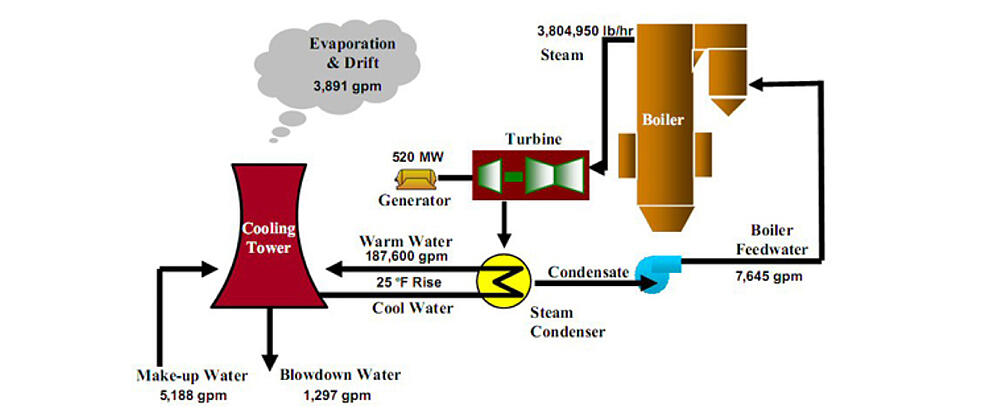

Electricity utilities are challenged by a competitive use of water in water scarce regions, and therefore need to rely on alternative water sources. Water use applications in electricity utilities include cooling tower make-up, boiler feed, environmental control, sanitation, irrigation of landscape and environmental stewardship. The day-to-day operation of a thermoelectric power plant, for example, is especially water intensive, and requires a large quantity of freshwater to sustain its ongoing activities (see image 1).

To address this pressing need for water in such large-scale quantities without exhausting freshwater supplies or competing with municipalities over local water resources, reused municipal wastewater can offer a feasible alternative water supply for the power sector.

Image 1 – Water usage in coal to power application (source: The National Energy Technology Laboratory)

Image 1 – Water usage in coal to power application (source: The National Energy Technology Laboratory)

Degraded or non-traditional water supplies are constantly being considered by the power sector to offset water consumption. However, although reclaimed wastewater appears an obvious choice due to geographic accessibility and unlimited availability, only 60 of 5,000 power plants across 16 states in the US currently use municipal reclaimed water (source: Bluefield Research).

One of these rare examples for a reuse-centric plant is Palo Verde – the largest power generator in the US with a total output of 4,030 net MW, which meets the electricity needs of approximately 4M people around the clock (source: WateReuse).

Because of its desert location, Palo Verde is the only nuclear power facility that uses 100% reclaimed water for cooling. The Palo Verde Water Reclamation Facility (WRF) is a 409K m3/day tertiary treatment plant that reclaims treated secondary effluent from local valley cities, and unlike other nuclear plants, it maintains Zero Discharge, meaning no wastewater is released to rivers, streams or oceans.

From Drain to Drink – The Added Value of Reuse for Potable Water Applications

The benefits of recycled water have already been proven across the world, and are continuing to lead the sustainable water resiliency movement. Reclaimed water is more cost-effective than developing other alternative supplies, it’s environmentally sound as it alleviates pressure on freshwater sources and natural systems, it’s safe – as water is purified to meet the strictest water quality standards, it’s sustainable – since wastewater is a constantly renewable source of freshwater, and lastly, it’s locally controlled. Communities are not obligated to drain natural water resources or rely on neighboring countries for their water supply – leading to full and comprehensive water independency.

<< Speak to a water reuse expert >>

Ways to Reduce, Reuse and Recycle water

Standard ways to reduce, reuse and recycle water usually include Ultrafiltration (UF), Reverse Osmosis (RO) and Ultraviolet Advanced Oxidation Process (UV/AOP) units. Chloramine, which is typically dosed in the RO process, helps to control biofouling of the membranes. However, chloramine is a precursor to the formation of disinfection byproducts such as NDMA – a dangerous organic contaminant and a suspected carcinogen.

The presence of chloramine not only increases the risk of membrane oxidation in the case of overdose, but also acts as a free-radical scavenger. This is more energy-intensive, entails chemical involvement and larger treatment systems that demand higher CAPEX and OPEX.

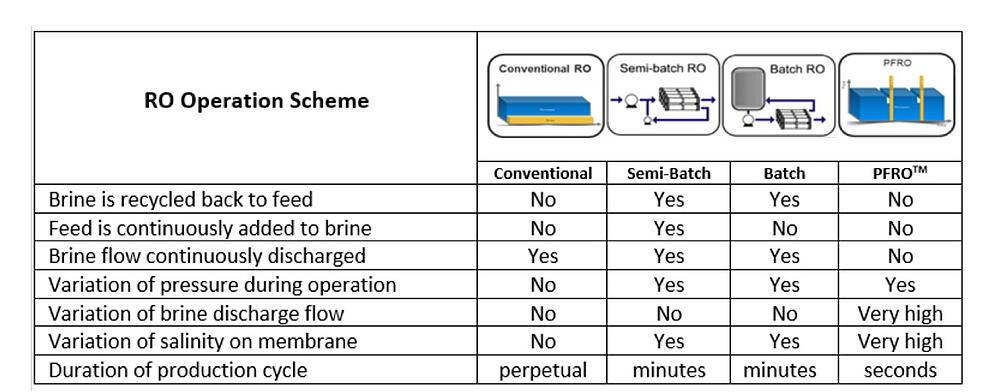

To overcome this problem, IDE has developed the Pulse Flow Reverse Osmosis (PFRO™) technology, that is completely Chloramine-free. As oppose to standard RO systems that operate under continuous hydraulic and osmotic conditions, the PFRO™ process utilizes alternating hydraulic conditions, switching between dead-end production mode and flushing mode, during which brine is flushed out at high velocity.

The constantly changing hydraulic conditions make it very hard for microorganisms to sustain themselves, thereby reducing the risk of biofouling and scaling. This allows the system to operate at very high flux rates (50% higher than normal), eliminating the risk of rapid increase in biofouling and resulting in overall CAPEX savings of about 20%.

Another advantage of PFRO™ is simpler design. Since brine is flushed periodically at high velocity, it’s no longer necessary to maintain constant brine flow, and the common staged design is no longer needed. All pressure vessels are installed in parallel without any inter-stage booster pumps or piping, meaning recovery that is normally achieved after three stages – can now be achieved in one single stage.

Case Study – The Central Coast Blue in Pismo Beach, California

Like many other places, California has been severely impacted by droughts during recent years. As the State continues to face a shortage of fresh water, advanced water reuse is proving to be a sustainable alternative for a clean, efficient and safe water source.

The Central Coast Blue Advanced Water Purification Demo Facility in the City of Pismo Beach, California, USA (Source: IDE)

The Central Coast Blue Advanced Water Purification Demo Facility in the City of Pismo Beach, California, USA (Source: IDE)

To address this growing need and prove the effectiveness of water reuse for municipal use, IDE PFRO™ technology was demonstrated in the City of Pismo Beach California – the Central Coast Blue Advanced Water Purification Demo Facility – from October 2018 to September 2019.

The Pismo Beach demo facility operated with a capacity of 164 m3/day, demonstrated a high recovery rate of 86% in a single RO stage, and operated with an average flux of 16.5 GFD (28 LMH), which is 50% higher than the standard design of 11 GFD (18-19 LMH). Showcasing the energetic efficiency of the process, the specific flux was high as well – and stood at about 0.12 GFD/PSI.

Unlike the common practice that prevails in most municipal wastewater reuse applications, no chloramine was dosed, and therefore no disinfection byproducts were formed. The chloramine-free operation generated permeate with an Ultraviolet Transmittance (UVT) value of about 100%, saving 30-40% on CAPEX and OPEX in the final UV/AOP stage.

Results prove that the process can be performed without chloramine dosing, while keeping the membranes mechanically intact and with very little fouling or scaling, and while keeping the overall water cost of this process up to 28% lower than a standard Fully Advanced Treatment (FAT) water reuse process.

Table 1 – PFROTM parameters vs. Conventional, Semi-Batch and Batch RO technologies

Table 1 – PFROTM parameters vs. Conventional, Semi-Batch and Batch RO technologies

Our ground and surface water supplies are at risk of overuse around the world, and it’s only a matter of time before demand will become greater than the water supplied by rain, rivers, lakes and reservoirs. Water conservation, wastewater recycling and reuse are gaining more and more focus as sustainable, feasible and very practical ways to alleviate industrial and municipal water demand intensity and ensure water resilience.

<< Speak to a water reuse expert >>

Sources

- WateReuse

- Bluefield Research

- Singapore’s National water Agency

- “The Four National Taps of Singapore: A Holistic Approach to Water Resources Management from Drainage to Drinking Water”, by Kim Irvine, Lloyd Chua and Hans S. Eikass, National Institute of Education, Nanyang Technological University; Public Utilities Board, Journal of Water management Modeling

- Frontiers in Environmental Science – Wastewater Management

- UNESCO 2017