Water is the lifeline of a community. It powers industry, sustains agriculture, and supports our daily life. However, ensuring our water infrastructure remains strong.

Strategies for Meeting US Industrial Waste Water Treatment Regulations

Our last few blog posts have looked at the challenges facing owners/operators of industrial plants – increasing reuse of process water, as well as better management and reduction of effluent discharge – and the changes that are becoming unavoidable in this sector.

As discussed, one of the main drivers of the search for innovative technologies and new methods for addressing effluent discharge are the increasingly strict regulations being put in place to govern said effluent discharge, following worldwide recognition of the need to preserve the environment.

This post will take a closer look at some of these waste water treatment regulations in the US, and solutions from IDE’s portfolio of technologies that can help plant owners/operators in general, and industrial plant owners/operators in particular, comply with the regulations.

You can be quite sure that if compliance with these regulations is giving you a headache, non-compliance will hurt more than just your head. The cost of non-compliance can be hefty, ranging from localized fines, to plant shutdown for implementation of corrective actions!

The Clean Water Act (CWA) establishes the basic structure for regulating discharges of pollutants into the waters of the United States and regulating quality standards for surface waters. The original CWA was, in fact, enacted way back in 1948 and was called the Federal Water Pollution Control Act. In 1972 the Act was significantly reorganized and expanded.

Under the umbrella of the CWA, the US Environmental Protection Agency (EPA) has developed national water quality criteria recommendations for pollutants in surface waters, as well as produced a comprehensive Guide for Industrial Waste Management, with the objective of providing facility managers, and regulators with recommendations and tools to better address the management of the large quantities of waste generated by, inter alia, industrial water treatment facilities.

Federal water quality criteria define the maximum permissible levels of various pollutants that will ensure the protection of marine life and human health. Water quality standards are developed to maintain this quality of water, and the responsibility for these standards rests at State level.

In addition to permitted pollutant levels in discharge streams, the volume of discharge is also regulated. Waste streams should be recycled and/or reused, and then treated, in order to meet quantity and quality regulations for discharge.

So, how are pollutant levels defined and measured, you might well ask. By the TMDL of course! And just to be sure that we are all clear on what a TMDL is – a total maximum daily load (TMDL) is a regulatory term defined in the U.S. Clean Water Act, that identifies the maximum amount of a pollutant that a body of water can receive while still meeting water quality standards. And who ensures that water quality standards and TMDLs are being met?

- The National Pretreatment Program; and

- The National Pollutant Discharge Elimination System (NPDES) Permit Program

TMDL is a regulatory term defined in the U.S. Clean Water Act

TMDL is a regulatory term defined in the U.S. Clean Water Act

<< Watch our “Solving the Power Industry Challenges” on-demand webinar >>

The National Pretreatment Program

Responsibility for the control of 126 priority pollutants from industries that discharge into sewer systems (CWA, Section 307(a), and listed in 40 CFR Part 423 Appendix A) lies with The National Pretreatment Program. These priority pollutants fall into two categories:

- Metals, including, for example, lead, mercury, chromium, and cadmium. These metals can’t be destroyed or broken down by treatment or environmental degradation and can cause various human health problems such as lead poisoning and cancer.

- Toxic organics, including solvents, pesticides, dioxins, and polychlorinated biphenyls (PCBs). These can be carcinogens, and can also lead to other health issues, such as kidney and liver damage, anemia, and heart failure.

<<Contact one of our experts to ensure you meet these criteria>>

The National Pollutant Discharge Elimination System (NPDES) Permit Program

The EPA develops national wastewater discharge standards – Effluent Guidelines – on an industry-by-industry basis. These are technology-based regulations and are intended to represent the greatest reductions of pollutants that are economically achievable for an industry.

The standards for direct dischargers are incorporated into National Pollutant Discharge Elimination System (NPDES) permits issued by States and EPA regional offices, and permits, or other control mechanisms for indirect dischargers

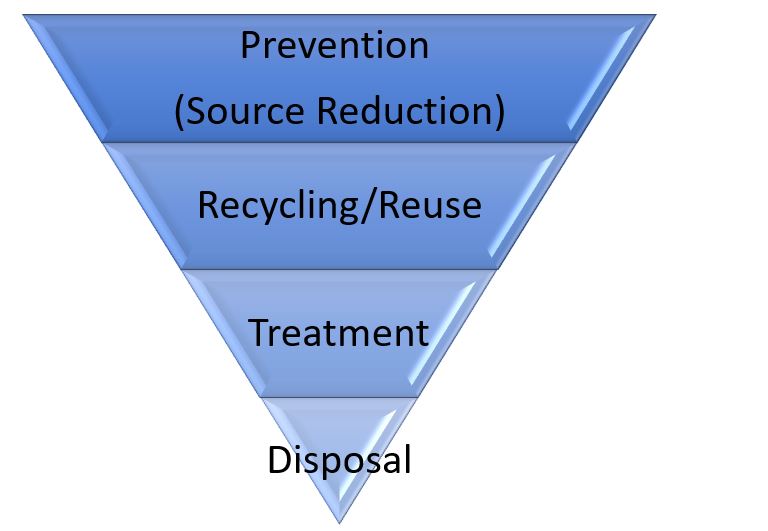

So, now we have named the “nasties”, what do we do about these? Preventing pollution requires a comprehensive, holistic approach; an approach that looks at an entire facility – from its physical design, through its production processes and products, with the aim of identifying how to mitigate and minimize environmental impacts across the facility. And the age-old adage that prevention is better than cure, applies here too, as can be seen in the Pollution Prevention Act of 1990, a national, 4-step policy.

-

Examination of waste streams and technologies to identify opportunities for recycling and/or reusing wastewater

-

Reducing volume and contamination of waste prior to final disposal to reduce costs and comply with regulations

-

Minimum amount to authorized sites, MLD or ZLD are high priority

-

Any practice that reduces pollution prior to recycling/reusing treatment, and/or disposal. Proper maintenance of filters and membranes.

All well and good in theory you might say, but how do you implement this in practice?

IDE offers several technologies and services to help you transform this idyllic theory into a reality that can be implemented and sustained, allowing you to comply with discharge regulations, and – as an added bonus in many instances – reduce your operating and discharge costs!

<<Contact one of our experts>>

Where IDE Enters the Picture

Reusing and recycling the waste stream: Can you reduce the waste streams that will ultimately be discharged? Yes, you can – and this will help meet regulations, and as a bonus, reduce discharge costs.

A reminder – these terms are similar, though not identical. Recycling is using the treated water again in the same process while reusing is treating the waste stream and using the treated water in a different process in the facility.

The IDE proprietary MaxH2O technologies excel in their ability to reduce the industrial water effluent streams. Hand-in-hand with the ability to treat and reduce effluent streams, these technologies also generate high-quality permeate that can be reused and/or recycled in any process in the facility, or shared with the community, for example for use in landscaping.

IDE offers a range of technologies for waste stream treatment, from reduction through to ZLD. Our MaxH2O technologies can be designed into new plants or retrofitted into existing facilities. Implement one of these technologies sooner rather than later – remember, prevention is better than cure.

Thoughts to Take Home

- Wastewater treatment regulations are becoming ever more stringent – nothing new in that. It’s well known and well documented. Regulations are not limited only to the amounts you can discharge, but also address the levels of pollutants that can be discharged. So, you need to be sure that you are discharging as little as possible, and that what you do discharge does not exceed the permitted levels of “nasties”.

- If you’re looking at a new facility, make sure that you design in the latest and most efficient technologies for wastewater treatment.

- If your plant is already up and running – recycle, reuse and treat waste streams prior to discharge.

- Consider options for retrofitting new technologies into already operating plants.

- Make sure you have a solid monitoring system in place, and contingency plans in the event of a problem.

- Be proactive with regard to malfunctioning or deteriorating equipment

- Identify and characterize the source of any contamination.

- Identify and evaluate potential corrective measures.

Our tailored water treatment solutions have been implemented worldwide, and some have been operating for decades. Our solutions help many industries including mining, power, petrochemical, chemicals, data centers, microelectronics, semiconductors, and refineries, tackle and overcome their water treatment challenges including meeting any local regulation needs.