Deionization Process

Industries rely on deionized water (DI water) for a variety of applications due to their high purity. DI water is commonly used as feed water for boilers, process water, and other applications that require demineralized water.

In wastewater treatment, the deionization process is typically implemented downstream of a reverse osmosis system. To maximize water recovery from the waste stream, IDE’s unique high-recovery solutions including MaxH2O, are often installed prior to the deionization stage.

Ion Exchange – Mixed bed

Ion exchange is a method in water treatment in which one or more undesirable ionic contaminants are removed from the water by exchange with another ion that is attached to the ion exchange resin. Both the contaminant and the exchanged substance must be dissolved and have the same type of electrical charge (positive or negative).

For deionized water, there is a need to remove all the remaining ions and leave only water, hence the ion exchange resin is exchanging the remaining ions from the water with hydrogen and hydroxides.

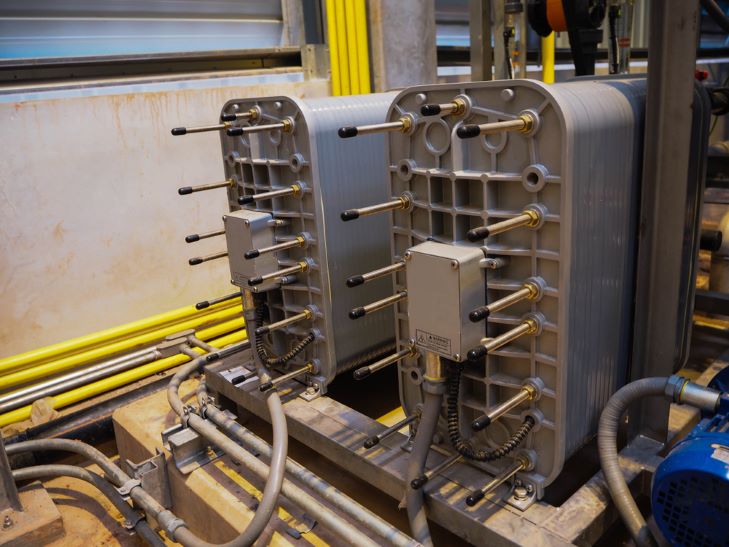

Electrodeionization (EDI)

Electrodeionization (EDI) is a water purification technology that combines ion-exchange resins and electricity to remove ionized species from water. It’s commonly used in applications where high-purity water is required, such as power generation, microelectronics, and others.

The basic principle of EDI involves applying an electric field to ion-exchange resins and membranes. Water flows through the EDI stack, where ion-exchange resins and membranes remove dissolved ions. Ions are captured by the resins and then transferred through the membranes into concentrate streams (brine), which are then discarded or further treated. The process continuously regenerates the resins, eliminating the need for chemical regeneration (Chemical-Free Regeneration).

Continuous Electrodeionization Systems (CEDI)

The CEDI process uses an ion-exchange resin, ion-exchange membrane, and direct current to continuously deionize water without using any chemicals.

With our chemical-free regeneration technology, continuous deionization is achieved without the need for chemical treatments, reducing both costs and environmental impact.

IDE has successfully used, for the first time, large-scale CEDI systems to provide high-capacity ultra-pure water (with a continuously guaranteed conductivity lower than 0.1 microsiemens/cm), in its Dos Bocas Petrochemical Pretreatment Project in Mexico.

Ready to elevate your water treatment process? Contact IDE today to discover how our cutting-edge deionization and ultra-pure water solutions can meet your industry’s specific needs.

Ready to elevate your water treatment process? Contact IDE today to discover how our cutting-edge deionization and ultra-pure water solutions can meet your industry’s specific needs.

Related Solutions

All solutions

Contact an Expert