As AI adoption accelerates, data centers have become the physical backbone of the digital world, powering everything from virtual assistants to predictive analytics and.

Water Treatment Plant Refurbishing & Retrofitting: To Do Or Not To Do

The truth of the matter is that there is no question here – in today’s world of awareness of preserving the planet and its natural water sources, there is no question that many industries, particularly older facilities, have to either refurbish, retrofit, or both.

Increasing urbanization and population growth are further straining already strained existing surface water and wastewater treatment infrastructures. Your wastewater treatment plant has already been operating for several years, and although operating quite well, is not able to keep up with the increased demand. Out with the old and in with the new? Possible – but this is an expensive option. However, you can refurbish existing equipment and retrofit new systems to help equipment and processes keep pace with the increased demand.

Also, it’s not news that preserving the environment is the name of the game! Are your existing wastewater treatment systems, equipment, and technology able to cope with new and increasingly stringent environmental discharge regulations? Unless your plant is new, the answer is probably not. You can retrofit new technologies as stand-alone units after your treatment process to help you meet the requirements of effluent discharge, and avoid penalties associated with non-compliant discharge.

Are your existing water treatment systems, equipment, and technology able to cope with new and increasingly stringent environmental discharge regulations?

Are your existing water treatment systems, equipment, and technology able to cope with new and increasingly stringent environmental discharge regulations?

Wastewater Plant Refurbish or Retrofit – Preferably Both?

Although these are similar processes, and often go hand in hand, they are, in fact, different. Retrofit is to add or substitute new parts or components to some device, structure, etc., that were not previously available; to modernize, while refurbish is to rebuild or replenish with all-new material; to restore to original (or better) working order and appearance (WikiDiff).

Zoom in on Retrofitting New Technologies

The vast majority of industrial plants use water in their process and generate waste streams from a variety of sources. These all require disposal. There are several different reasons that drive the need for better industrial effluent treatment – regulatory pressure, increasing environmental awareness, etc. Reducing the effluent discharge, particularly from industrial facilities, is one of the greatest challenges facing the water treatment sector.

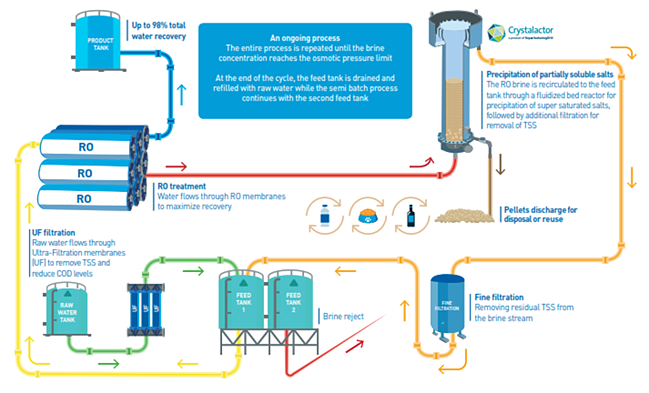

IDE offers innovative, cutting-edge technologies that push the boundaries of industrial effluent treatment. Our unique MaxH2O technologies overcome the factors that limit the recovery of RO plant – osmotic pressure and the chemistry of the feed water. What’s more – these solutions can be designed into new plants, or retrofitted into existing facilities. This technology achieves recovery of up to a remarkable 98%!

We are very aware that not all facilities face the same challenges, and therefore the same solution does not work for all. For this reason, we offer two different MaxH2O solutions, depending on the issues you are facing. If the source of your headache is scaling, the Desalter and Crystalactor combination is the way to go. However, if it’s biofouling that causes your pain, PFRO followed by flushing the membranes with a cleaning agent is probably the solution for you.

MAXH2O Desalter for industrial effluent treatment is a semi-batch RO plant with an integrated salt precipitation cycle for continuous desaturation of industrial effluents.

Why choose our MAXH2O Desalter? To let you in on just some of the reasons:

- Up to 98% recovery

- High flexibility – operates with variable feed water qualities, concentrations, and flows

- Pushes the precipitation limits of sparingly soluble salts

And the cherry on the top – low investment and operational costs!

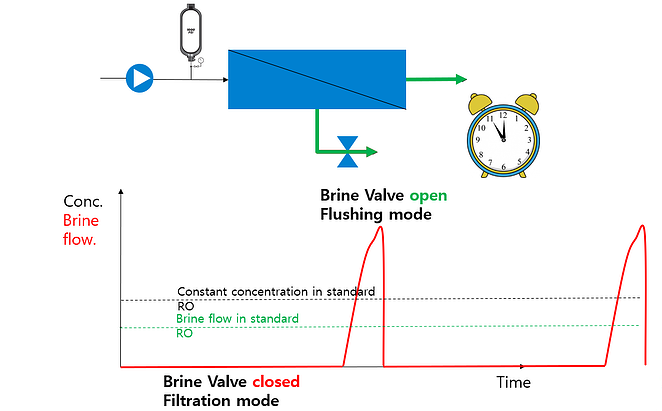

MAXH2O PFRO is revolutionizing the conventional RO desalination process. For almost half a decade, continuous brine flow has been an unshakeable foundation of the conventional RO desalination process. MAXH2O PFRO makes the leap from continuous to pulse flow, which allows achieving a significantly higher solute concentration in the brine flow, as well as higher recovery rates.

Why choose our MAXH2O PFRO? We can’t tell all, but some of the reasons are:

- Prevents bio- and other types of fouling

- Reduced power consumption due to intermittent brine pumping, and diminished pressure drops in stages

- Fewer vessels and membranes required – a single-stage structure without inter-stage boosters reduces the cost

MaxH2O Desalter – a Bird’s Eye View

MaxH2O Desalter – a Bird’s Eye View

MaxH2O Pulse Flow RO (PFRO) Solution

MaxH2O Pulse Flow RO (PFRO) Solution

<< Contact one of our experts >>

Refurbishing is No Less Important!

Your water and wastewater treatment equipment are subject to continuous wear and tear, resulting in more frequent breakdown and repeat visits for parts and services. Equipment breakdown means plant downtime, and this is an expense. Be pre-emptive – upgrade underperforming equipment! Take the necessary steps to minimize repairs and keep your equipment operating in peak form for years to come. You can extend the lifetime of wastewater treatment equipment!

As part of our belief in a holistic approach to water treatment facilities, IDE in-house experts can help you maximize the potential of your existing facility and refurbish it to meet your current needs. This can go hand in hand with retrofitting – implementing innovative and cutting edge technological solutions that will also drive your plant towards a more efficient and ecological operation. We offer you the chance to capitalize on our operational experience, creativity, and thorough knowledge of leading technologies and the deployment of integrated solutions for refurbishment. And we do this with minimal disruption to the existing RO plant and operation!

Why choose IDE for refurbishing an existing plant? Let’s just say, refurbishment can

- Increase productivity with limited plant area or budget.

- Have a financial Impact – reduce chemical and energy consumption

- Help you achieve tangible savings as a result of higher production at lower operation costs

Retrofit, Refurbish, or Both – In a Nutshell

If you’re not going to go the path of “out with the old and in with the new” for your entire facility, which will overcome all your challenges but bears a hefty price tag, one way to make quality improvements, take advantage of new technologies and save time and money over buying new is by retrofitting or refurbishing, or both.

- IDE’s cutting-edge technologies for minimizing effluent and maximizing recovery can be designed into new plants, but can also be retrofitted into existing facilities! Meet new regulations and tomorrow’s challenges today!

- Our environmental responsibility is demonstrated by the implementation of innovative and eco-friendly solutions minimizing any impact on natural water sources and the environment

- When designing a refurbishment, we make every effort to minimize Capex and preserve as many as possible of the existing systems.

- Our refurbishment services allow you to keep equipment operating effectively and efficiently for longer. This will free a valuable budget for ongoing operation and maintenance activities.