As the demand for freshwater intensifies globally, desalination has become an essential technology for addressing water scarcity. However, the disposal of brine,.

Desalination can – and does – co-exist in harmony with the environment

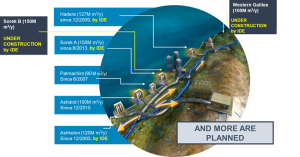

Israel is a small state with a single coastline, and 7 mega-size desalination plants built or planned along this strip of coast, for a length of approximately 200 km, currently producing some 80% of Israel’s potable water. These desalination plants are among the largest operating plants worldwide, firmly positioning Israel as an expert on the subject of effluent discharge in general and its impact on the environment in particular. The brine stream generated during the desalination process is also discharged along this same strip of coast. Therefore it is essential to ensure that all relevant regulation is in place to ensure that there is no negative impact on the precious environment.

The impressive map of desalination along the Israel coastline is a testament to the success and sustainability of both the technology and its environmental management and firmly positions Israel as a role model for the harmonious co-existence of desalination and the environment.

Mega Size Desalination Plants along the Israel Coastline

What goes in must go out

Currently, 595Mm3 of desalination water is produced annually, and a similar amount of brine is discharged to the sea from the operating plants. This significant number could be expected to have an impact on the marine environment. However, correct handling, in compliance with the proper environmental regulations, has proven that this is not the case. The impact to the marine environment is, in fact, negligible. Theoretical studies before the plant construction and practical operation have shown that desalination plants and the marine environment can – and do – co-exist in perfect harmony.

Environmental Aspects

The Israel Ministry of Environmental Protection provides strict environmental policies for proper management and mitigation of the variety of environmental challenges expected due to the construction and operation of desalination facilities, with the main challenge being to ensure the preservation of the marine environment. These environmental policies are relevant at all life stages of the desalination plant – from construction through to operation.

Who regulates desalination activities?

All aspects of desalination plant construction and operation in Israel are governed by three official bodies:

One of the main objectives of the Ministry of Environmental Protection policy is the prevention of harm to the marine environment, including but not limited to risks of sea pollution as a result of plant activity, the impact of the concentrated discharge water on the marine environment, and its mitigation, reduction of the quantity of solids discharged to the sea, and minimizing the amount of phosphorus and suspended solids discharged into the sea.

The discharge of organic substances to the sea is forbidden, including water from periodic membrane cleaning (CIP).

Reporting – an integral part of the Environmental Policy

At the bid stage – environmental issues of concern are considered from the very outset, during the bid stage. Bidding companies are required to submit a detailed survey on all environmental aspects of the project, including mitigation and possible solutions. This Preliminary Environmental Survey (at the bid stage) is a significant consideration in the evaluation of proposals and should reflect the bidder’s environmental approach.

During construction and operation stages – environmental issues of possible concern are divided into those expected during the construction and operation stages, with the operation stage further sub-divided into marine impacts and impacts on the terrestrial environment and atmosphere (Lokiec, 2013). As impacts during the construction stage are transient, we’ll look more closely at impacts during the operational stage, which is ongoing and long-term.

Potential impacts on the terrestrial environment and atmosphere during the operation stage are caused at various points in the plant and include, inter alia, alteration of the coastal environment and obstruction of free passage along the seashore; emission of noise, greenhouse gases, and air pollutants; accidental spill or leak of hazardous chemicals; solid waste and sanitary sewage; lighting interference, and aesthetic impacts.

Potential impacts on the marine environment are considered at various points of the plant and include habitat alteration and changes in sediment transport; entrainment and impingement of marine biota; debris pollution; biological effects of residual chlorine and chlorination by-products; effects of residual chemicals and particulate matter in the effluent.

Concerns related to the marine environment are addressed by proper dispersion of the discharged brine stream and correct handling of the residual chemicals and particulate matter in the effluent by sludge treatment.

Outfall Aspects

The design aspects of intakes and outfalls have been discussed in detail in the literature (Missimer, 2018; Voutchkov, 2011), and selecting the most appropriate location for the effluent discharge from the plant poses a challenge of its own. Areas to avoid include those with large populations of endangered species and stressed marine habitats; and areas with frequent naval vessel traffic, which could damage the outfall facility and change mixing patterns. A location with strong marine currents that allow quick and effective dissipation of the concentrate discharge is preferable, as is a location as close as possible to the shoreline to minimize outfall construction expenditures without compromising the intake water quality.

Near Shore Discharge – Hadera Desalination Plant

Environmental Impact Assessment (EIA)

An EIA is performed during the planning stages of the plants and includes, inter alia, modeling of the brine dispersion to optimize the outfall design to achieve maximum dilution. The assessment addresses several other issues related to discharge dispersion and recirculation, effluent toxicity; all this with the purpose of ensuring that the discharge water quality meets the quantitative and qualitative quality standards applicable to the point of discharge.

Residual Chemicals and Particulate Matter

Despite the significant reduction in the use of chemicals in the desalination process during recent years, as in any other water treatment plant, some usage of chemicals is inevitable. These chemicals include ferric salts as a coagulant additive for enhancement of filtration prior to the filtration step, antiscalants, Caustic Soda and Sulfuric Acid/CO2 for pH adjustment in the different stages of RO treatment, flocculant, limestone, lime water, and hydrochloric acid, and others as required. Most chemicals are NOT discharged with the brine streamby the use of neutralization, while some are treated and incorporated into the sludge formed in the treatment process.

- All chemicals used in the desalination processes comply with the Ministry of Health requirements for the treatment of drinking water.

Operation Reports

The Ministry of Environmental Protection defines very clear requirements for effluent discharge from the desalination facility in accordance with the renewable Discharge Permit granted to the plant.

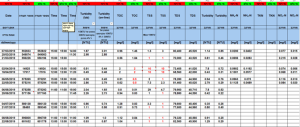

- Some reports are required daily and online, including discharge quality as measured by the online sensors. Full water chemistry analysis is required every two weeks. Other parameters are reported on a monthly basis, such as turbidity of the discharged brine, marine monitoring, and more.

- Figure 5 shows an example of a typical monthly report according to the requirements of the Ministry of Environmental Protection.

Typical Desalination Plant Monthly Report

Marine Monitoring Reports- Marine Surveys

As part of the brine discharge permitting process, biannual compliance monitoring surveys are conducted to assess the effects of brine discharge on the receiving marine environment, and findings are reported to the Ministry of Environmental Protection. Results are compared to those of previous years to evaluate environmental impacts and changes as a result of the plants’ activity. The marine surveys use a sampling scheme comprised of a number of planned stations for discrete seawater sampling and additional stations to follow the spatial dispersion of the brine plume for each plant. The number and location of these additional stations are based on the actual brine dispersion pattern encountered during the preliminary survey.

The monitoring reports are publicly available on the website of the Ministry of Environmental Protection.

Sampling Points for the Hadera Desalination Plant

These requirements – although complex and time-consuming – are the key to successful desalination plant operation while preserving the marine environment. This has allowed sustainable desalination in Israel for 17 years of operation since the first operation of the Ashkelon desalination plant.

Several researchers have studied the effects of desalination plant effluent discharge on the marine environment, and results across the board agree that there is no detrimental effect. The paper by Nurit Kress (2019), Seawater quality at the brine discharge site from two mega size seawater reverse osmosis desalination plants in Israel (Eastern Mediterranean) is particularly interesting; it examines two local plants along the Israel coastline and because the data is recent. The paper shows clearly that the effluent quality meets all requirements.

CONCLUSIONS

Driven by need and supported by decision-makers, in less than a decade, Israel moved from limited natural resources to water independence. Almost 600 Mm3/year of desalinated water is produced, supplying a significant portion of the Country’s drinking water. Today, Israel’s ability and technological readiness to independently address the gaps in demand for water are exceptional on any international scale.

While the reliance on desalination plants for water production provides Israel with resilience, it also poses a challenge to the preservation of vulnerable environmental sources due to the disposal of the plant effluent back to the sea.

Results of continuous monitoring have clearly demonstrated the viability, economy, and sustainability of the technology as a viable alternative source of drinking water for the State of Israel.

The success of the original master plan can be attributed to 3 main reasons

- The vision of decision makers that identified the need for this solution and their obstinacy to implement it.

- The robust management base was created to support the preparation, design, and implementation of the first BOT contracts, as well as realistic WPAs that allow long-term engagement of both sides.

- Creation of a regulatory system, albeit complex and demanding, that allows the regulator continuous control of plant performance, and guarantees full compliance of the final desalinated water and the brine discharged to the sea with the stipulated quality, thus protecting the marine and coastal environments.

The efforts invested in the follow-up of the plants have given the green light for the progressive implementation of the 5 plants already in operation and the 6th and 7th under construction by IDE.